Taking Full Advantage Of Efficiency: Selecting the Right Aftermarket Construction Parts for Your Fleet

Taking Full Advantage Of Efficiency: Selecting the Right Aftermarket Construction Parts for Your Fleet

Blog Article

Opening the Cost-Saving Benefits of Aftermarket Components for Heavy Equipment

When it concerns heavy machinery maintenance, the option in between initial tools producer (OEM) components and aftermarket parts is a choice that holds significance beyond the surface area. The market for aftermarket parts has actually been continuously growing because of numerous factors that make them an attractive choice for cost-conscious businesses seeking to enhance their upkeep budget plans. By checking out the cost-saving benefits of aftermarket components, one can reveal a world of prospective advantages that not only effect the monetary base line yet also the operational effectiveness of hefty machinery.

High Quality Efficiency at Lower Prices

The premium top quality efficiency provided by aftermarket components for hefty equipment comes with dramatically lower prices contrasted to OEM parts. Aftermarket components suppliers have actually had the ability to bridge the gap in between top quality and affordability, providing a cost-effective option for organizations looking to keep and fix their heavy equipment without jeopardizing on performance. These parts go through extensive screening procedures to ensure they satisfy industry criteria and specs, providing a level of integrity that is on par with OEM parts.

One key benefit of aftermarket parts is their affordable rates, which can result in considerable cost savings for services in the future. By selecting aftermarket components, companies can access top quality parts at a portion of the cost of OEM components, enabling them to assign their sources more efficiently and effectively. Moreover, the accessibility of aftermarket components from a variety of vendors enhances competitors on the market, driving rates down and giving consumers a lot more choices to choose from when sourcing elements for their heavy machinery. Generally, the mix of quality efficiency and lower expenses makes aftermarket components an engaging option for organizations seeking to optimize their repair and maintenance spending plans.

Varied Series Of Options Available

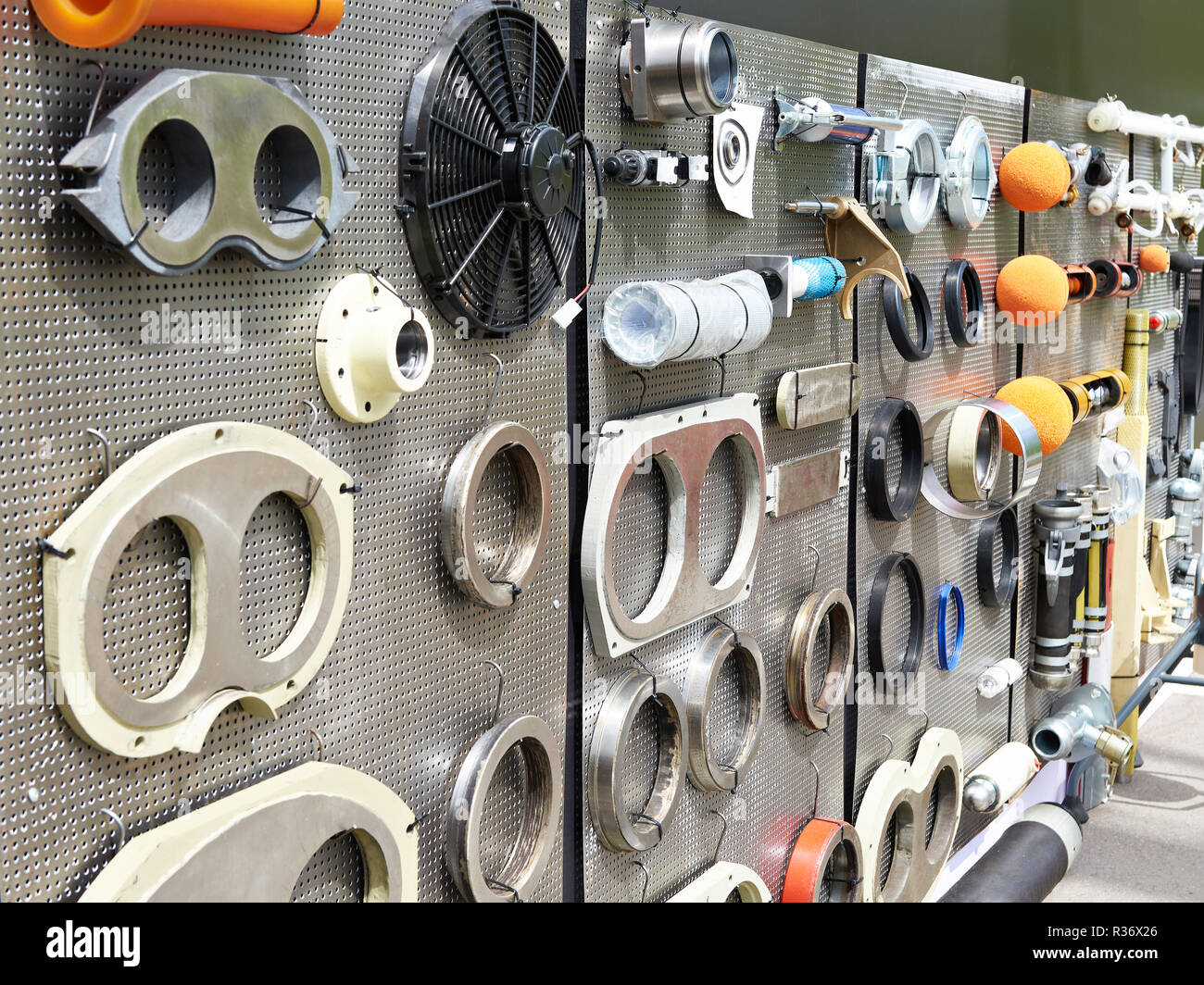

In the middle of the aftermarket parts market for hefty machinery, a myriad of diverse alternatives stands ready to deal with the certain demands and demands of businesses. This considerable variety of aftermarket parts offers organizations the adaptability to choose products that line up carefully with their equipment requirements and budget plan restraints. From engine elements to hydraulic parts, filters, undercarriage parts, and much more, organizations can pick from numerous aftermarket options tailored to various machinery brands and models.

In addition, the aftermarket parts market gives businesses with the chance to discover choices that might not be offered with initial devices makers (OEMs) This variety in alternatives allows organizations to find economical services without compromising on quality or efficiency - aftermarket construction parts. Whether a business focuses on longevity, cost competitiveness, or details efficiency characteristics, the aftermarket components market provides a large option to meet these unique choices

Compatibility With Various Machinery Brands

By providing components that are created to fit flawlessly with equipment from various brands, aftermarket suppliers enable organizations to simplify their upkeep processes and inventory monitoring. This flexibility in compatibility likewise suggests that firms can settle their parts sourcing efforts, reducing the moment and resources spent on browsing for details parts for every device in their fleet.

Additionally, the capability to utilize aftermarket parts across different equipment brands can result in price savings for services. Instead of counting exclusively on original tools producer (OEM) components, which can be much more expensive, business can utilize aftermarket options that offer similar high quality at a more affordable price factor. This cost-effective technique to components procurement contributes to general financial savings for heavy equipment drivers while making certain that tools continues to be functional and reliable.

Quick Schedule and Easy Access

With the boosting need for efficient upkeep services in the hefty equipment market, timely schedule and hassle-free accessibility to aftermarket components have become vital for companies looking for to maximize their procedures. Quick availability of aftermarket components ensures that equipment downtime is minimized, enabling business to return to operations swiftly without prolonged interruptions. This not only boosts productivity however additionally avoids profits loss connected with prolonged periods of inactivity.

Easy access to aftermarket components is equally visit this page crucial as it improves the maintenance process (aftermarket construction parts). Upkeep teams can swiftly procure the essential elements without comprehensive lead times or delays when parts are readily easily accessible. Refined accessibility to aftermarket components look at here also improves general operational efficiency by reducing the moment and initiative called for to resource and replace components, eventually contributing to set you back savings and better devices uptime

Boosted Worth for Maintenance Budgets

Moreover, the minimized lead times connected with aftermarket parts make it possible for companies to simplify their upkeep processes. By enhancing upkeep budgets with the utilization of aftermarket parts, businesses can achieve a competitive side in their market while sustaining earnings and functional excellence.

Conclusion

Finally, aftermarket components for hefty equipment offer an economical option for maintenance needs. These parts supply quality efficiency at lower prices, with a diverse variety of alternatives readily available for various equipment brand names. Their fast availability and easy gain access to make them a convenient selection for upkeep budgets. Overall, making use of aftermarket parts can unlock considerable cost-saving benefits for businesses looking for heavy equipment maintenance.

When it comes to heavy equipment upkeep, the choice between initial devices maker (OEM) parts and aftermarket parts is a decision that holds value past the surface click to read more area.The premium quality performance used by aftermarket parts for heavy machinery comes at significantly lower expenses compared to OEM components. These components go through extensive screening processes to guarantee they meet market criteria and specs, using a level of integrity that is on the same level with OEM components.

By opting for aftermarket components, business can access high-quality components at a fraction of the price of OEM components, allowing them to allot their resources a lot more successfully and successfully. Aftermarket components typically come at a portion of the price of OEM parts, permitting companies to extend their maintenance budgets further and allot sources to various other crucial locations.

Report this page